Kína Kórházi kereskedelmi orvosi berendezések Gyártó, szállító, gyár

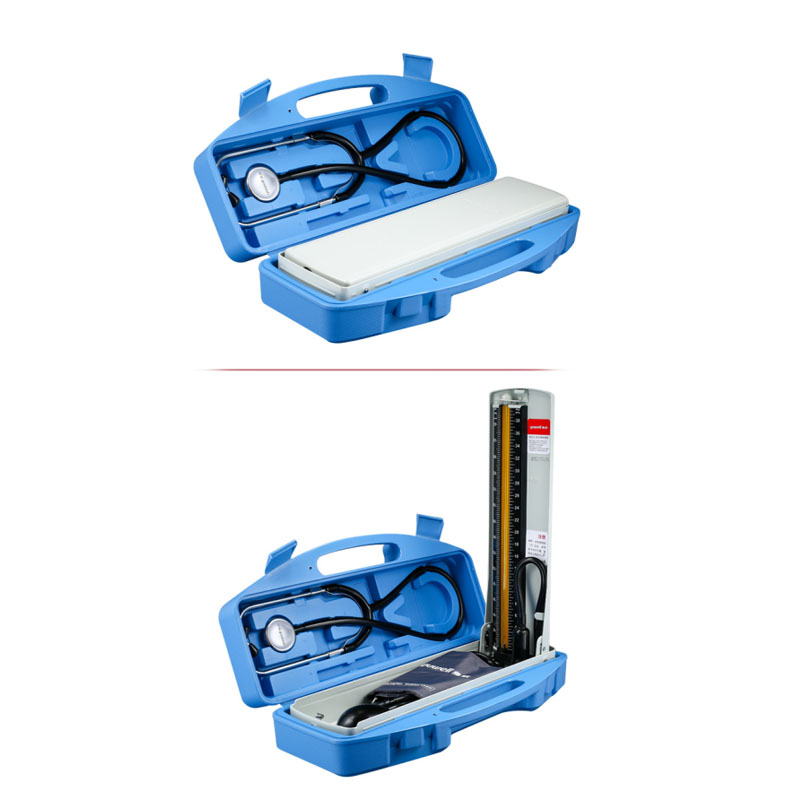

Hospital commercial medical equipment includes: Trauma treatment vehicle, operating table, operating light, Monitor, Anesthesia Machine, Ventilator, blood cell analyzer, Differentiation Analyzer, microplate reader, Plate washer, Urine analyzer, Ultrasound instrument, X-ray machine, thermometer, blood glucose meter, stethoscope, Masks, protective clothing and other protective equipment, Medical gel plaster dressing, nursing bed, blood pressure chart, microscope, physiological recorder, CT scan, magnetic resonance, B-ultrasound, Counter, Common surgical instruments, Immunoassay instruments, Light guide surgical instruments, Laser treatment machine, endoscope, biomedical analyzer, thermometer, blood glucose meter, stethoscope, biomedical analyzer, thermometer, blood glucose meter, stethoscope

Mould for Hospital commercial medical equipment

P&M is a mold factory with more than 10 years of experience in Hospital commercial medical equipment molds. We can achieve the desired product effects through injection molds, blow molds, rotational molds, and die-casting molds. At the same time, we have two factories, both of which cover an area of more than 5,000 square meters. We have sufficient equipment and professional engineers to fully meet all customer needs.

In terms of product materials, most of the shells of Hospital commercial medical equipment are made of ABS materials, and the screens of Hospital commercial medical equipment are made of optical materials, such as PC materials, PMMA materials, PETG materials, etc. We usually use PC. We have a complete supplier of raw materials, and we can provide customers with any mold materials they want.

In terms of design, Hospital commercial medical equipment requires that the parts fit very well. The perfect fit and assembly between parts have a great effect on the quality of the product. For example, the shell of the operating light adopts a curved surface design, and the lower part of the operating light shell fits closely with the lower part, making the appearance quality of the operating light very high, and the light transmittance meets the requirements of users. At the same time, different designs are also very important for the role of products. For example, thermometer, blood glucose meter and other parts will make people very convenient and comfortable to use. The curved surface combined with the human hand structure design makes it more convenient for people to use the product. We have a certain study on the structural mechanics of the human body, and we can do the design that customers want.

In terms of mold materials, it depends on the product structure, product quantity and customer budget requirements. For relatively simple structures, we can use P20 and 718 mold materials, and the mold life can reach 150,000-300,000 sets. For some complex and special structures, we need to use S136 or H13 mold materials, and the mold life can reach 500,000-100 sets. We will provide the best and most suitable mold material selection, so that customers can use the most suitable budget to make the most satisfactory product effect. We have experience in cost, and I can also recommend the most suitable mold material for customers.

The services we provide are all one-stop services, 1. Product design-2. 3D drawing production-3. CNC sample testing/3D printing testing-4. Mold production-5. Product production-6. Product packaging-7. Product transportation. We are a complete supply chain that can meet the needs of all customers.

Hospital commercial medical equipment mold description

We can fully meet customer requirements

1.Automation.

2.Suitable for high-speed injection.

3.Long mold life.

Mold cavity: 1 cavity-4 cavity-8 cavity, depending on customer needs

Mold size: 800x800x980mm, depending on customer needs

Applicable machine: 450T-1150T

Mold main material: P20 718HH H13 S136 2738

Mold injection system: 1 point self-leveling gate

Mold ejection system: unloading plate from injection side

Mold cycle time: 15-30 seconds

Mold run: 800K

Delivery time: 25 working days

- Alapvető testreszabási szolgáltatás

- Egészségügyi ellátás

- Elektronikus készülékek és műszerek

- Anyai és gyermekkellékek öntőformái

- Szabadidősportok

- Lakberendezési művészet

- Autó tartozékok

- Szállítás és raktározás

- Világítótestek

- Építőipari berendezések

- Csomagoló termék

- Oktatás és laboratóriumok

- Ruházat Csomagkiegészítők

- Ápoló és tisztítószerek

- Mezőgazdaság és Erdészet

- Mechanikai berendezések

- Kisállat kellékek

- Konyhaedények

- View as

Mikroszkóp öntés

A Ningbo (P&M) Plastic Metal Products Co., Ltd. 17 éves penészgyártási technológiával rendelkezik, és testreszabhatja a mikroszkóp öntését. Professzionális testreszabott mikroszkópos penész szolgáltatásokat nyújtunk, és professzionális mikroszkópos penészgyártó vagyunk. Elegendő tapasztalattal rendelkezünk a termék nyersanyagok és penészanyagok kiválasztásában. A mikroszkópos formák testreszabása során gyárunk egyablakos szolgáltatást nyújthat. A mikroszkópokkal kapcsolatos tervezési és termelési képességek, például: CAD tervezés, penészgyártás, fröccsöntés, műanyag termékek előállítása, összeszerelése és egyéb technológiák.

Olvass továbbKérdés küldéseOrvosi vércukorszintű öntés

A Ningbo (P&M) Plastic Metal Products Co., Ltd. 17 éves penészgyártási technológiával rendelkezik, és testreszabhatja a vércukorszintmérő formákat. Professzionális, testreszabott orvosi vércukorszintű öntési szolgáltatásokat nyújtunk, és professzionális vércukorszintű penészgyártó vagyunk. Elegendő tapasztalattal rendelkezünk a termék nyersanyagok és penészanyagok kiválasztásában. A vércukorszint-mérőformák testreszabása során a gyárunk egyablakos szolgáltatást nyújthat. A vércukorszint -mérőkkel kapcsolatos tervezési és termelési képességek, például: CAD tervezés, penészgyártás, fröccsöntés, műanyag termékek előállítása, összeszerelése és egyéb technológiák. TIC terméktermelés, összeszerelés és egyéb technológiák.

Olvass továbbKérdés küldéseRöntgengép öntés

A Ningbo (P&M) Plastic Metal Products Co., Ltd. 17 éves penészgyártási technológiával rendelkezik, és testreszabhatja a borotva öntést. Egyedülálló betekintést nyújtunk a röntgengép-öntésbe, professzionális, testreszabott borotvaként szolgáló szolgáltatásokat nyújtunk, és professzionális borotválkozó-gyártó vagyunk. Elegendő tapasztalattal rendelkezünk a termék nyersanyagok és penészanyagok kiválasztásában. A borotválkozók testreszabása során a gyárunk egyablakos szolgáltatást nyújthat. A borotvakkal kapcsolatos tervezési és gyártási képességek, például: CAD tervezés, penészgyártás, fröccsöntés, műanyag termékek előállítása, összeszerelése és egyéb technológiák.

Olvass továbbKérdés küldéseUltrahang műszer öntés

A Ningbo (P&M) Plastic Metal Products Co., Ltd. 17 éves penészgyártási technológiával rendelkezik, és testreszabhatja az ultrahangos műszeres formákat. Professzionális, testreszabott ultrahangos műszer -öntési szolgáltatásokat nyújtunk, és professzionális ultrahangos műszeres penészgyártó vagyunk. Elegendő tapasztalattal rendelkezünk a termék nyersanyagok és penészanyagok kiválasztásában. Az ultrahangos műszeres formák testreszabása során a gyárunk egyablakos szolgáltatást nyújthat. Az ultrahangszerekkel kapcsolatos tervezési és gyártási képességek, például: CAD tervezés, penészgyártás, fröccsöntés, műanyag termékek előállítása, összeszerelése és egyéb technológiák.

Olvass továbbKérdés küldéseVizeletanalízis öntvény

A Ningbo (P&M) Plastic Metal Products Co., Ltd. 17 éves penészgyártási technológiával rendelkezik, és testreszabhatja a vizelet -elemző formázást. Professzionális testreszabott vizelet -elemző penész szolgáltatásokat nyújtunk, és professzionális vizelet -elemző penészgyártó vagyunk. Elegendő tapasztalattal rendelkezünk a termék nyersanyagok és penészanyagok kiválasztásában. A vizelet-elemző formák testreszabása során a gyárunk egyablakos szolgáltatást nyújthat. A vizelet -elemzőkkel kapcsolatos tervezési és gyártási képességek, például: CAD tervezés, penészgyártás, fröccsöntés, műanyag termékek előállítása, összeszerelése és egyéb technológiák.

Olvass továbbKérdés küldéseLemezmosó öntés

A Ningbo (P&M) Plastic Metal Products Co., Ltd. 17 éves penészgyártási technológiával rendelkezik, és testreszabhatja a lemezmosó öntését. Professzionális, testreszabott lemezes penész szolgáltatásokat nyújtunk, és professzionális lemosó penészgyártó vagyunk. Elegendő tapasztalattal rendelkezünk a termék nyersanyagok és penészanyagok kiválasztásában. A lemezmosó-formák testreszabása során gyárunk egyablakos szolgáltatást nyújthat. Vannak tervezési és termelési képességeink a lemezmosókhoz, például: CAD tervezés, penészgyártás, fröccsöntés, műanyag termékek előállítása, összeszerelése és egyéb technológiák.

Olvass továbbKérdés küldése